Technical Specifications

Table: N/A Work Fixture

X: 160 mm Y: 160 mm Z: 50 mm

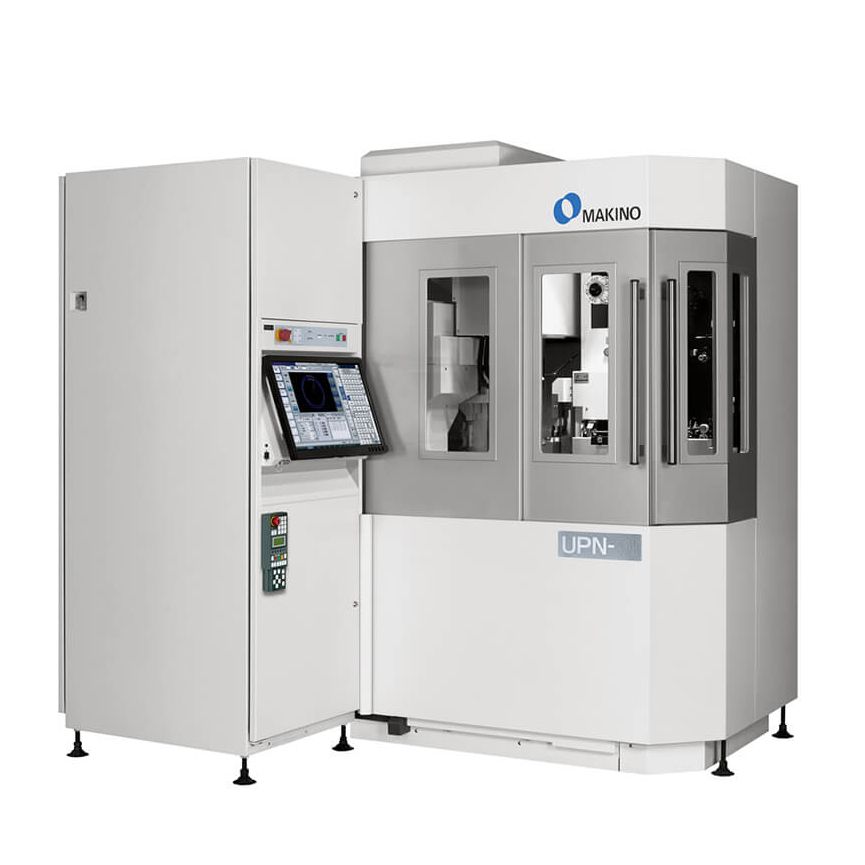

The UPN-01 uses an oil di-electric system that provides greater control of the machining spark gap, which improves part accuracy, surface finish, and metallurgical quality. The machine can achieve surface finishes down as low as 0.02µmRa (1µinRa). The entire work zone is also enclosed and is temperature controlled to minimize thermal changes to the machine and work piece during long hours of operation. The integrated ultra-high precision rotary C-Axis achieves indexing accuracies of ±2 Arc Seconds (±0.00056 degrees), and also facilitates automatic exchanging of the work piece for extended unattended operation. The machine can also be equipped with an automatic slug ejection system that further extends unattended machining capabilities.

The UPN-01 features Makino’s universal Hyper i control system, that provides the same streamlined and efficient user interface for both Wire and Sinker EDM machines. The Hyper i control features a user-friendly interface similar to that found on tablets and Smartphones, making operation very intuitive and straightforward. A large 24” class HD touch-screen display provides a commanding view for operation, and the Hyper i control also features many helpful intelligent tools for the operator. Digital onboard electronic manuals, instructional training videos, and advanced process control functions provide the operator with all of the resources necessary to remain highly productive. The UPN-01 is ideal for micro-machining and ultra-precision applications such as producing components for fiber optics, electronic connectors, medical, miniature gear, and micro molding industries.