Technical Specifications

Table: 4-Sided 910 x 710 mm”

X: 650 mm Y: 450 mm Z: 420 mm

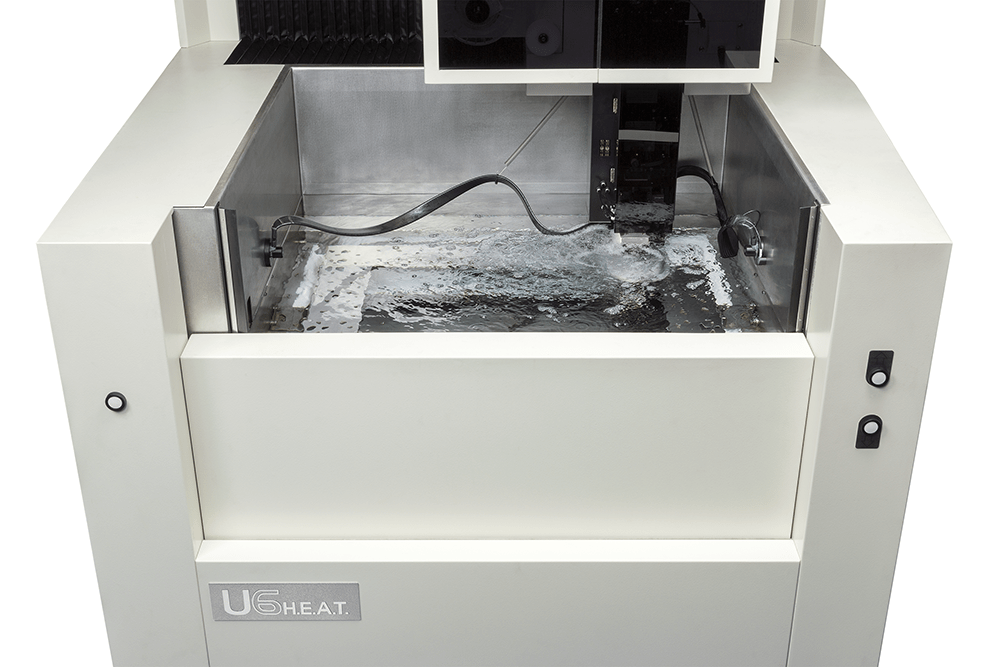

The U6 H.E.A.T. machine footprint is minimized with a space-savings design that integrates the di-electrode reservoir into the base machine casting, which also improves the machines thermal stability. Work tank access is excellent using the pneumatic raise and fall front door, and allows access to the underside of the work piece or lower machine head even with a large work piece on the table, and the door also has a mid-height level function for greater flexibility. The U6 H.E.A.T. utilizes a Split-V Wire Guide system that requires less maintenance and last 34 times longer than traditional Round Wire Guides. Machine maintenance and consumable wear items are also reduced when compared to traditional designs, which provides greater productivity while reducing operational costs.

As the industry leader in low wire consumption technologies, Makino has worked to reduce the single largest expenses in operating a wire EDM machine. The U6 H.E.A.T. contains a robust machining conditions library that has been developed to provide an optimal mix of Speed, Accuracy, Surface Finish, and Low Wire Consumption for both sealed and poor flush applications. The machine utilizes larger capacity independent dual flushing pumps, and harnesses this additional raw horse power to deliver higher pressure and volume of flushing to machining to reduce Rough Cut cycle time. The machine is also standard with a larger capacity (4) filter filtration system to support the higher capacity flushing capability, and are located in a non-submerged cabinet that includes an integrated Filter Air-Purge function that evacuates the water from the filters before exchanging, reducing the weight of the spent filter and preventing the traditional dirty, wet slip hazards that are normally encountered with filter replacement.

U6 H.E.A.T. enhancements from U6:

- Standard 4-Sided hardened work table

- Split-V Wire Guide System

- Higher capacity flush pumps (2 pumps)

- 4 Filter filtration system

- Higher capacity Chiller Unit

- Standard mouse & keyboard

- H.E.A.T. Technology for the High Speed machining of poor flush applications