Technical Specifications

X: 350 mm Y: 250 mm Z: 350 mm

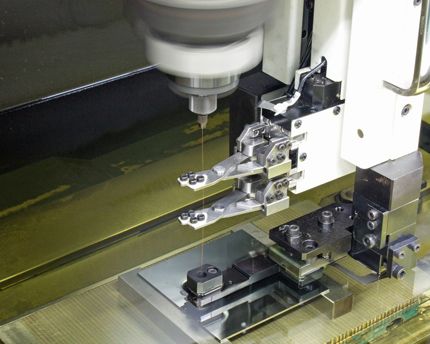

The EDAF2-Fine Hole machine contains a programmable W-Axis and Arm Structure that is independent but parallel to the Z-Axis, and this additional axis contains the Die Guide and Middle Guide support components for EDM Drilling operations. The W-Axis Middle Guides supports small diameter electrodes and prevents vibration or bending from occurring during machining, and the W-Axis Arm can be removed and installed on the machine in less than a minute using a series of quick disconnects and a rigid Curvic coupler. The EDAF2-Fine Hole machine is standard with a high speed C-Axis that provides precision indexing and continuous rotation speeds up to 2,000rpm, and a high pressure pump with 6MPa (870psi) or 10MPa (1,490psi) capability.

Industries and markets such as Aerospace, Automotive, Medical, and Die/Mold rely on the EDAF2-Fine Hole to be a productive solution for critical high accuracy hole details. The EDAF2-Fine Hole machine utilizes a traditional Ram EDM di-electric oil, which helps to provide dramatic game-changing improvements to accuracy, edge quality, and metallurgical characteristics to EDM Drilling capabilities. The machine incorporates the automation and operator friendly programmable Rise and Fall work tank, and is also equipped with a U/V Flame Sensor and Fire Extinguisher system for long hours of safe unattended operation. Makino’s advanced and streamlined Hyper-i control, which utilizes a 24” class high-definition touch screen, brings new levels of operational efficiency to the shop floor with its intuitive interface and practical support tools that enhance the capability of operators of all skill levels.