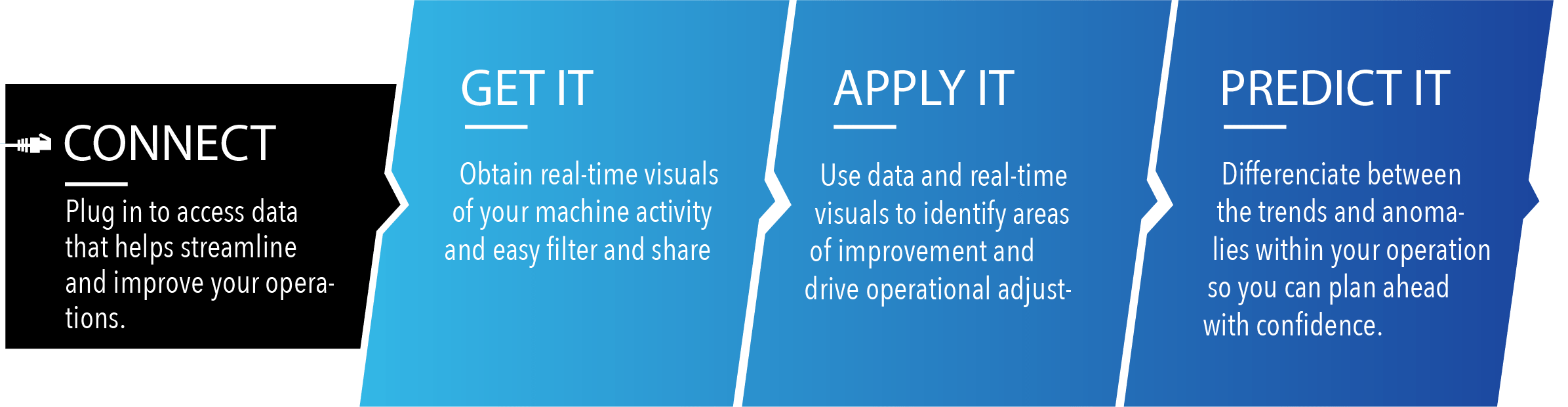

Connect Plan

When all your machines connect, everything starts to click

One network connects all of your machines, regardless of age or control builder.

With Connect Plan you can monitor the activity in your factory so that you can plan and predict machine performance and uptime.

Get real-time updates about your machines no matter where you are.

Smart Manufacturing

Okuma’s new Connect Plan provides analytics for improved utilisation by connecting machine tools and providing visual control of factory operations and machining. The software-based system monitors and collects data to fine-tune processes and improve productivity. The OSP control (accommodations can also be made for non-Okuma controls) connects to a PC installed with Factory Monitor suite. This enables the machine operation status to be visible from the shop floor, the office, or the smartphone.

Monitoring and Tracing

Email notification of machine alarms can be checked and the Okuma NET BOX suite-C even connects to machines from other manufacturers. Connect Plan achieves machining traceability by tying together the individual ID of a machined workpiece with the machining data and gauging results for each machine. If a problem occurs, the cause can be analysed and higher-quality production can be reinstated with greater assurance. In addition, the collected process data can be used to predict and schedule maintenance intervals.

Okuma’s remote diagnostics allows the screen from a customer’s machine to be viewed by a service engineer for accurate communication. This means that a diagnosis can be made while looking at the same screen. All available machine data can be collected, evaluated, and made available according to the customers’ needs.

Subscribe for Industry news, future events and more