Technical Specifications

Table: 300 mm x 340 mm

X: 450 mm Y: 620 mm Z: 500 mm

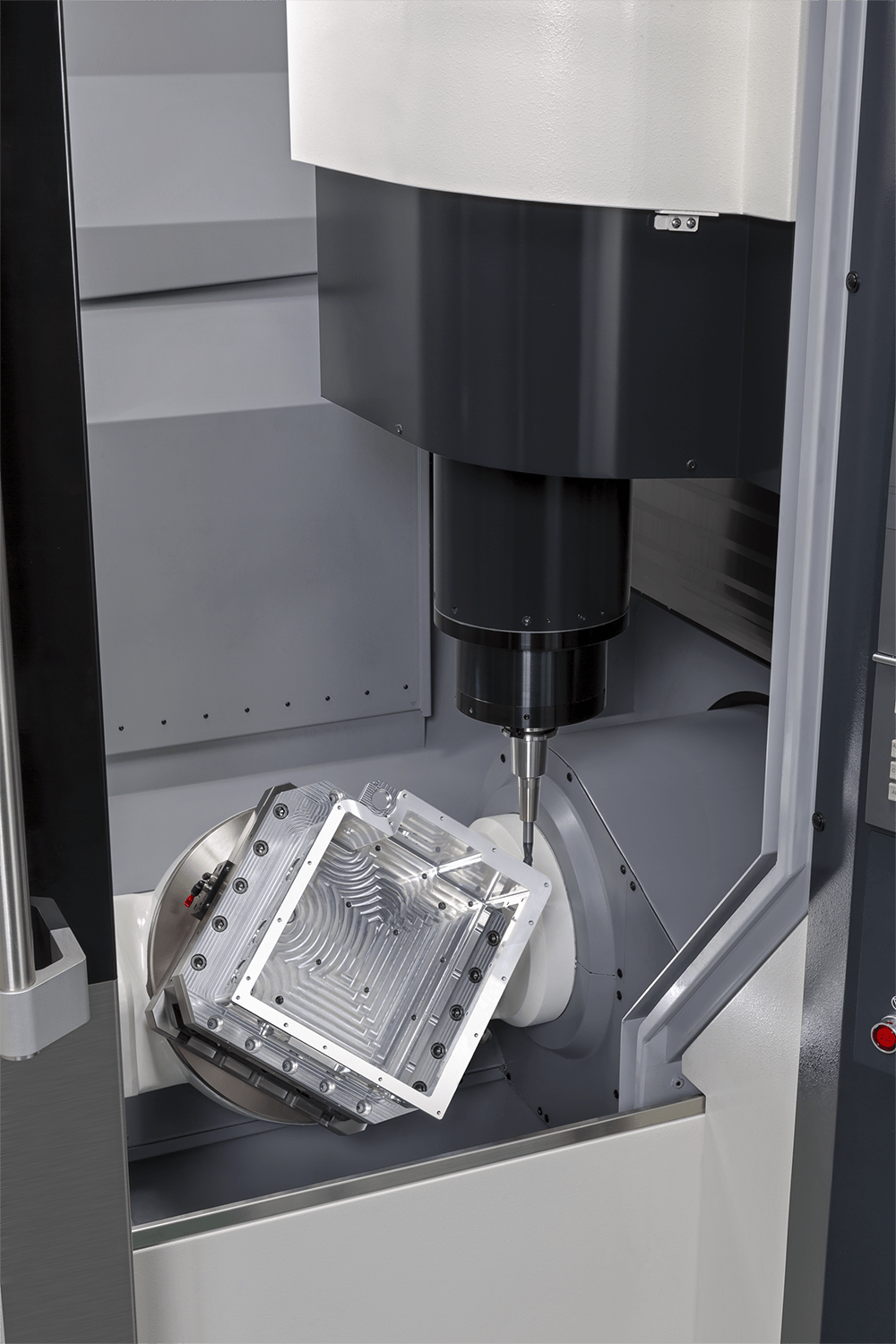

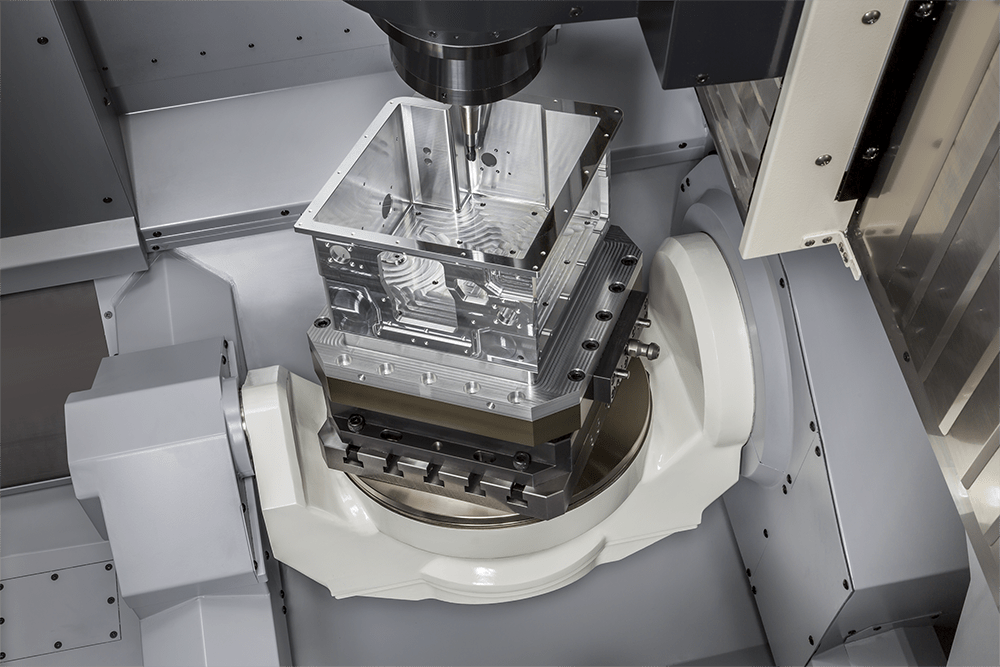

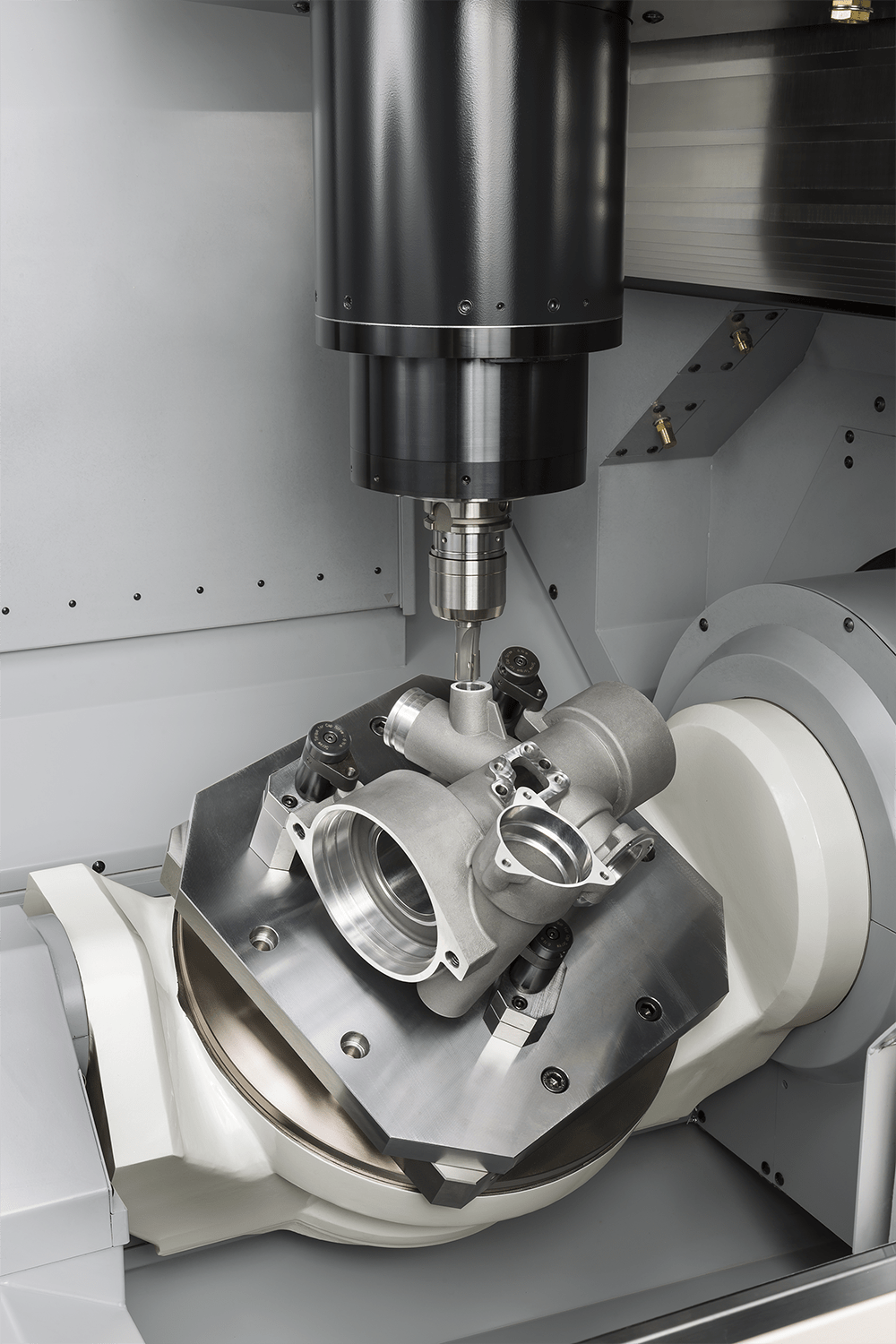

The DA300 Five – Axis Vertical Machining Center combines a rigid structure and high dynamic motion control to significantly reduce part cycle times while maintaining very accurate performance. Equipped with an integral, DD – motor designed A – Axis and C – Axis, the machine provides five – side access for single set-up production of complex production parts.

At 20,000 RPM, 29.5 HP, HSK–A63, the machine spindle provides the capability to tackle rigorous milling, drilling and tapping tasks associated with a wide variety of production parts. A standard, 60 tool magazine insures an extensive selection of tooling to address any part configuration.

To further minimize non – cut times, the DA300 is standardly equipped with a Vision BTS (Broken Tool Sensor) outside of the machine work zone to insure tooling integrity – but, not impact part cycle times.

The DA300 integral table rectangular table (340 mm x 300 mm) is prepared with pneumatic ports design to readily integrate into a pallet system providing for quick, efficient part exchange – maximizing machine utilization.

The Makino Professional 6 control takes you from parts to profits with elegant functionality by making the point where human meets machine a seamless transition. Streamlined screen layouts, operator assistance, new machine functions, and safety enhancements are accelerating and protecting your productivity. For even greater productivity, Super Geometric Intelligence 5 (SGI.5) insures optimum performance during execution of the tool path – producing the shortest cycle times.

Standard Features:

- Sixty (60) Tool Magazine

- 20,000 rpm, 2 range, HSK–A63 Spindle

- Automatic Spindle Lubricant Temperature Controller

- Tilt-Trunion Table (A & C axes)

- Integral Table (13.4” x 11.8”)

- Machine temperature control:

- “Core Cooled” Ballscrews

- Support bearing & drive motor

- A & C Axes DD Motors

- Vision BTS

- Automatic Lubrication Supply Unit

- Base Coolant

- Nozzle Coolant

- 210psi Through Spindle Coolant

- Overhead Shower Coolant

- Right Discharge LUCC

- Splash and Chip Shield

- Makino Professional 6 Control

- Makino Proprietary Super Geometric Intelligence SGI.5 Software

- Data Center (1 GB)

- Part Program Storage (2 GB)

- Tool Offset Pairs (400 Total)

- Rigid Tapping

- Rigid Tap Retract Function

- Five Axis Software:

- TCP – Tool Center Point Control

- DFO – Rotary Table Dynamic Fixture Offset

- TWP – Tilted Work Plane Command

- Three Dimensional Cutter Compensation

- Inversed Time Function

- Program Restart

- 3-Dimensional Manual Feed;

- Spindle-Table Interference Prevention Function

- Collision Safeguard

- Custom Macro (1,100 variables)

- Helical Interpolation

- Portable MPG

- Air Dryer

- Maintenance Advice System

- Inch/Metric Selection

- Fluorescent Worklight

- Programming Data Input (G10)

- Spindle Load Display

- Spindle Load Monitoring

- Tool Life Management

- Direct Spare Tool Selection

- Dual Safety Check

- Signal Light (3 layer)6